It’s not every day you get to unbox one of the first five beta units from a premier tech startup.

Cameron Turner, Engineering Director at Desire2Learn and founder of MakerClub, was presented his beta Discov3ry Paste Extruder by the Structur3D Printing team Thursday at the Communitech Hub.

The completed beta units enable 3D printers to print paste materials and marks yet another milestone for the Kitchener company who we first met last year as part of Communitech HYPERDRIVE’s fourth cohort.

They launched their crowdfunding campaign on Kickstarter in July, surpassing their initial $30,000 goal in just two days. Now, they’re working hard to ship units out to their beta backers within the next two weeks.

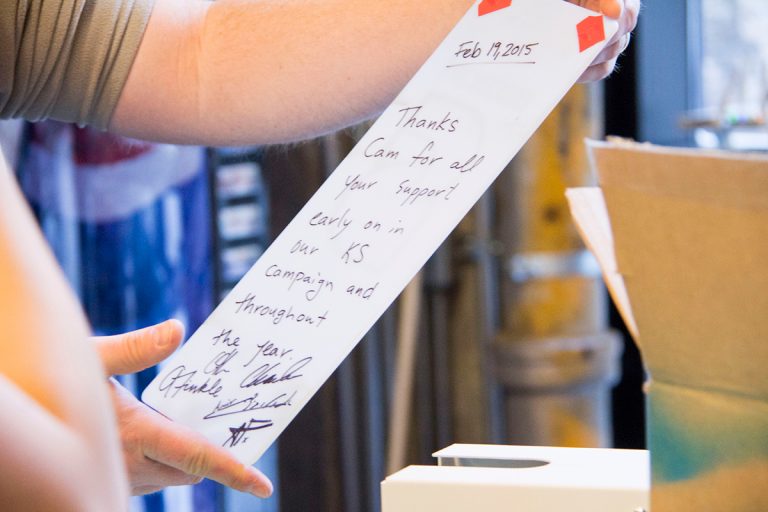

Cameron Turner holds a hand-written note the Structur3D team

included with his Discov3ry Extruder. (Communitech photo: Meghan Kreller)

“This is what we’ve been working towards. We’ve wanted nothing but to ship, but we wanted to ship a quality product,” said Dr. Charles Mire, co-founder and President of Structur3D.

“We’ve been having to balance that as best we can, and we feel that we’ve brought the product to a state where we’re happy to start shipping,” he said.

And the company continues to grow. They celebrated moving into their new headquarters in Kitchener in December and are now a team of five. They’ve been gearing up to ship the beta units by building and testing for quality control before sending them off. They even have a UPS representative helping them sort out logistics.

“It’s been busy, but exciting,” said Andrew Finkle, co-founder and Director of Research and Development.

They were happy to come to Communitech to present the unit to a local customer in the Waterloo Region tech ecosystem.

“The local community, the support from Communitech, that has all been extremely important during our early days of the company. Coming back to recognize that is certainly very meaningful,” Mire said.

Seven months after backing the startup, Turner was equally excited to unbox his extruder, complete with polypropylene cartridges, user manual, stickers and the solid metal unit with a personalized faceplate signed by the Structur3D team.

“It’s a lot heavier than I expected,” said Turner, who is happy to support the company who has been influential in the region’s maker community.

Turner has a 3D printer and figured he’d become a beta backer to introduce youth in the MakerClub to the many possibilities of 3D printing. They have already run successful sessions with Structur3D showing them how to print cookies and sweets, and notes his future is about to become even sweeter.

“The kids have lots of designs on using this. As soon as I get it hooked up to my printer, I foresee lots of frosted cookies coming out,” Turner said.

“We’ll probably send a set to each of my kids’ classes to share.”

Top photo: Cameron Turner (third from right) holds his new Discov3ry Paste Extruder delivered to him by Structur3D Printing team members (left to right): Olga Lioudvinevitch, Amir Solowiejczyk, Charles Mire, Andrew Finkle and Adam Finkle.